After our late start dismantling yesterday, today commenced around 11am with the goal of hopefully getting the engine out of the boat and on the deck somewhere. There wasn’t too much left. Essentially the goal is to disconnect everything from the engine so its just sitting there.

We had 2 major components left, the coupler and the forward engine mount bolts. The coupler is where the transmission has a plate where it bolts to a matching plate on the end of the propeller shaft. Yesterday we were able to remove 4 of the bolts but there is an adapter plate of sorts between the transmission and prop shaft so there were four more bolts to remove. The access wasn’t the most comfortable per say, but they came loose and I was even able to pull the bolts all the way out! Quite satisfyingly this left the transmission and the prop shaft to be able to turn independently, definitely disconnected.

The next major hurtle was the forward engine mount bolts. The engine is secured to the boat by four mounts, the rear two had easy enough access and all the bolts were able to be loosened and then removed without too much knuckle busting and hammering; however, the forward ones, with their limited access in the tight space, were a bit of a different story. After smacking away on our small ratchet supporting a slew of adapters and visegrips as leverage extenders, Heather returned from the store with a larger extender and socket for a larger wrench. Surprisingly, these came loose too after a bit of force!

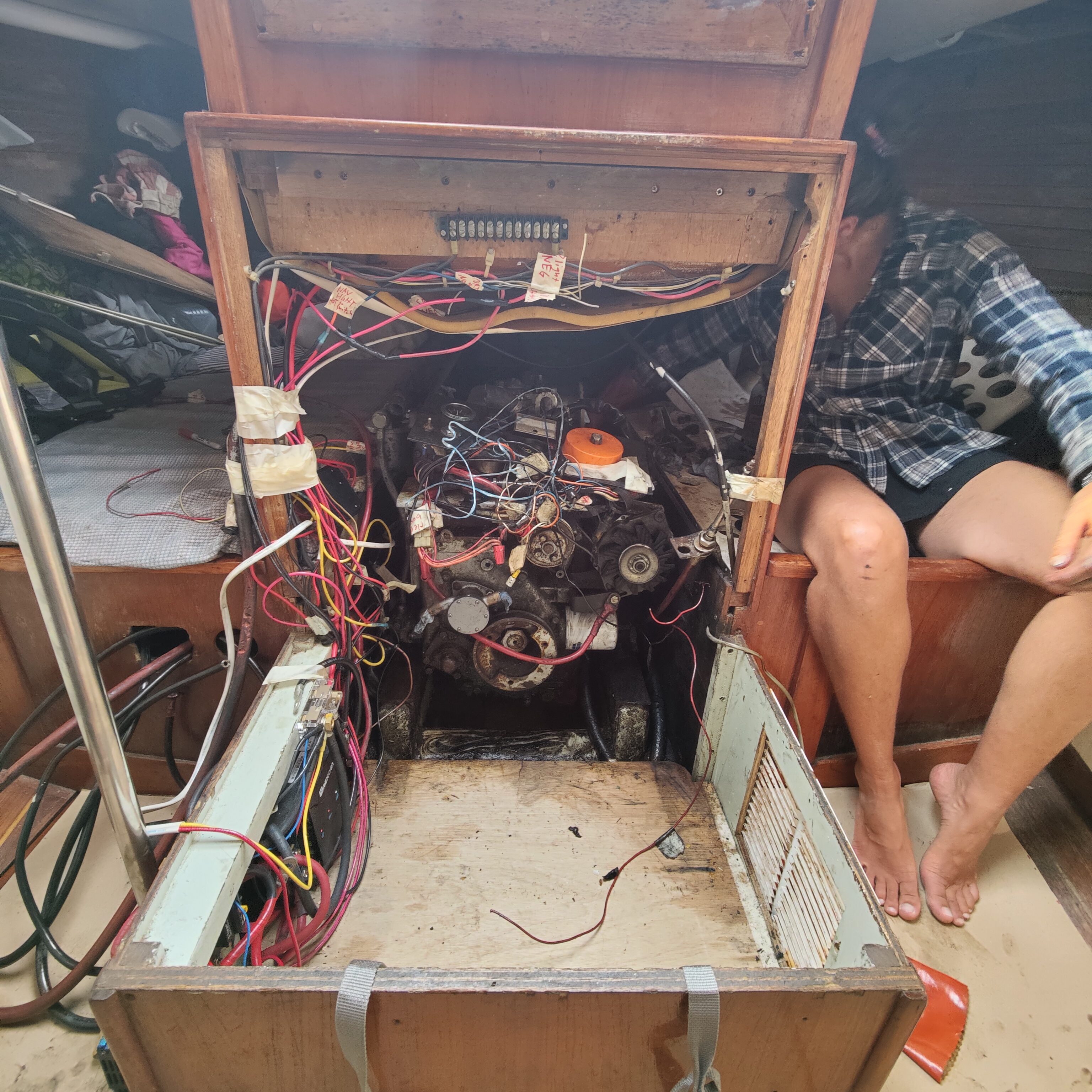

Now the electrical. Our engine wiring ‘harness’ was more of a hodgepodge of wirenuts and speaker wire. With the replacement 2GM20F comes the Yanmar wiring harness and panel, so we left all the engine wires attached and essentially just tied the ‘panel’ and wiring to the engine to be lifted out all as one piece. We just then had to clear a path for the engine by removing our house bank batteries and taping all the house wiring out of the way.

At this point we attempted to lift or just jiggle the engine to see if it’d come loose. It does! We took our dodger down so we could use the main sheet and the boom to lift the engine straight out of the companion way. After a bit of fiddling it was clear we were going to have to zip off the two forward engine mount bolts. Out comes the oscillator and they’re gone in a matter of minutes, how to lift this beast out.

Weighing in at probably 120kgs or so, its not too heavy as far as an engine goes, but it is still a large, very solid, block of iron. With the main sheet attached at its lifting point I started cranking slowly from the cockpit as Heather used our huge heavy wooden dinghy oars to sort of wedge and guide the engine first up off the bolts and then forwards. While it was rather heavy to lift with the block and tackle, a sailboat is rather well setup for this sort of thing and it wasn’t too much of a big deal to get more mechanical advantage using our array of winches onboard.

A bit of cranking, a bit of wedging with paddles, a bit of cranking, some leveraging with paddles, out the engine lifted! We placed a board across our traveler and cockpit seats to pull the engine out and place on while we re-situated the lines to move the engine out of the way of the companion way. It is a bit unwieldy to move about, and we did end up getting a line stuck on a winch in a bind we may have to cut to get loose, but we were able to get the engine safely and securely on a cockpit seat on a piece of wood.

At this point the boat is of course a mess. We have ram-board over the floors inside which are totally covered in oil and other sticky black substances, everything outside is filthy with oil and stuff, but the engine is out! The evening encroaches in so we put the major stashes of tools away for the night and hit the Ucluelet Brewing Company for a much deserved beer or 5. Tomorrow, scrubbin’ day in preparation to paint it pearly white. That engine room is going to sparkle.

Day 2, 10h30 – 19h00:

- Coupler disconnected

- Engine mount bolts removed

- Electrical panel disconnected

- Wiring Harness untangled and tied to engine

- Engine mount bolts cut

- Batteries removed

- House wiring sorted and moved out of the way

- Engine removed from engine bay

- Engine placed and tied down in cockpit

- 5 beers consumed

Leave a reply to Murat Cancel reply